When tackling tough materials like metal, wood, or plastic, a Sawzall, Milwaukee’s iconic brand of reciprocating saw, is a must-have powerhouse in your toolbox. But whether you’re a seasoned professional or a weekend DIY enthusiast, one question always arises: Are Sawzall blades universal?

The quick answer? Not exactly. While many reciprocating saw blades are designed with a standard shank that fits most brands, important factors like blade length, tooth design (TPI), material composition, and cutting purpose vary widely. These differences impact performance, fit, and even safety. For example, can Sawzall blades cut through concrete and stone? Yes, but only with the right heavy-duty blade type, such as carbide-tipped or diamond-grit designs, which are specifically engineered for hard masonry materialsKnowing how to match the right Sawzall blade to your material and job type is key to getting fast, clean, and efficient cuts every time.

Are Sawzall Blades Interchangeable Across Brands?

The simple answer is yes, mostly, but with a few important caveats. Most Sawzall blades, especially those featuring a universal shank, are designed to fit a wide variety of reciprocating saws across different brands. Major power tool brands like Milwaukee, DeWalt, and Bosch all follow the standardized shank design, making their blades easily interchangeable.

However, there are some exceptions you should watch out for:

- Proprietary blade systems: Certain high-end or specialized saws may use exclusive shank designs that only work with their own brand’s blades.

- Older reciprocating saw models: These may not accept modern universal shank blades, limiting your options.

- Non-standard mounting systems: A few off-brand or specialty tools might use a unique blade mount, making compatibility an issue.

So, while universal Sawzall blades work across most major brands, always double check compatibility, especially if you’re working with a lesser-known manufacturer or an older saw model.

Key Factors That Affect Sawzall Blade Compatibility

Choosing the right Sawzall blade isn’t just about grabbing any blade off the shelf. Several key factors determine how well a blade will fit your reciprocating saw and how efficiently it will cut through materials like wood, metal, plastic, or even concrete. Here’s what you need to look at:

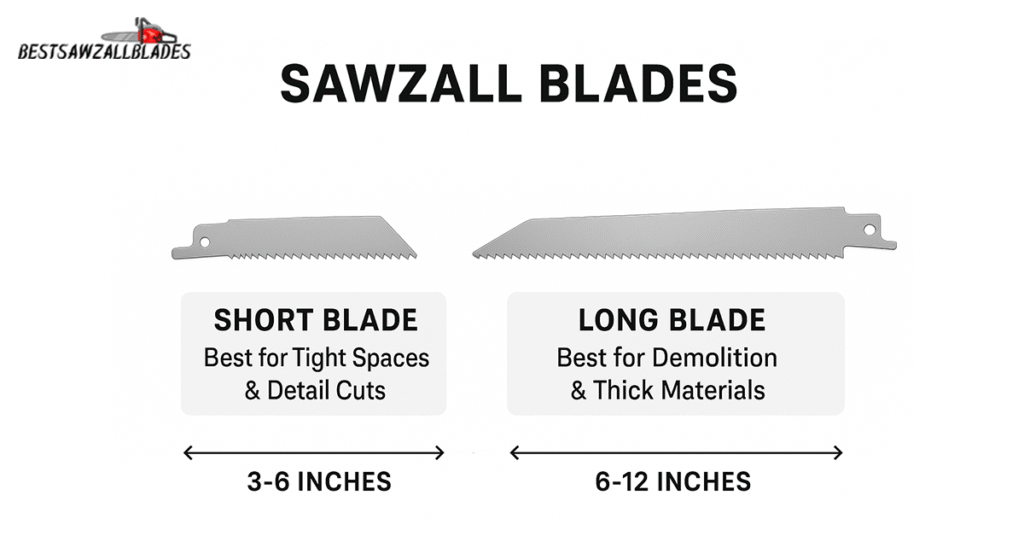

1. Blade Length

One of the first things to check is blade length. Sawzall blades typically range from 3 to 12 inches, and your choice should match the scale of your job:

- Short blades (3–6 inches) are ideal for tight spaces or detailed cuts.

- Long blades (6–12 inches) offer extended reach and are better suited for demolition or cutting through larger materials like thick lumber or pipes.

2. Blade Shank Type

The shank is the end of the blade that locks into the saw. Most modern reciprocating saws use a universal shank, making it easier to swap blades across brands.

- Universal shank: Most common and widely compatible. Fits major brands like Milwaukee, DeWalt, Makita, and Bosch.

- SDS-plus or SDS-max: These are specialty shanks designed for high-performance or heavy-duty tools, often used in professional trades for concrete or masonry cutting.

Always double-check the shank type to ensure compatibility with your specific saw.

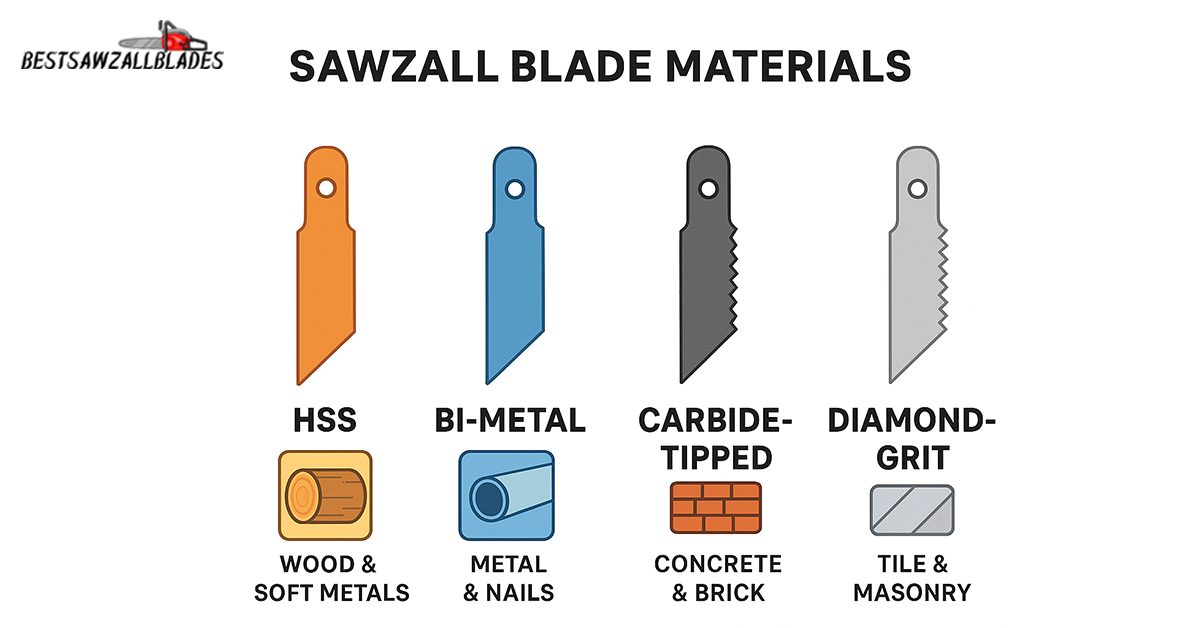

3. Blade Material and Tooth Design

Not all blades are built the same. The material and teeth pattern greatly affect how a blade performs:

- High-Speed Steel (HSS): Best for general use on wood and soft metals.

- Bi-metal blades: Combine HSS with cobalt for added durability. Perfect for metal, nails, and mixed-material jobs.

- Carbide-tipped blades: Designed for the toughest jobs, cutting through brick, concrete, fiberglass, or ceramic tile.

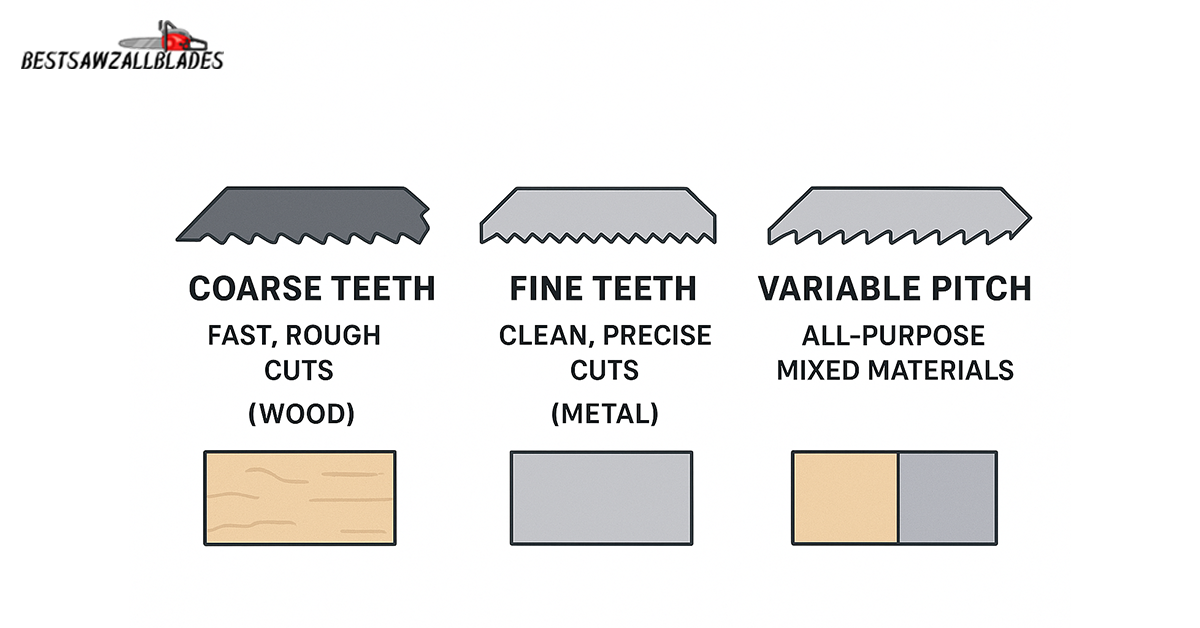

Tooth design also matters:

- Coarse teeth = faster, rough cuts (ideal for wood).

- Fine teeth = slower, cleaner cuts (ideal for metal).

- Variable pitch teeth = versatile for mixed materials, offering both speed and control.

This is where TPI teeth per inch comes in. What does TPI mean on a Sawzall blade, and why does it matter? Simply put, a higher TPI means finer, cleaner cuts (great for metal), while a lower TPI gives faster, rougher cuts (ideal for wood and softer materials).

4. Blade Thickness and Width

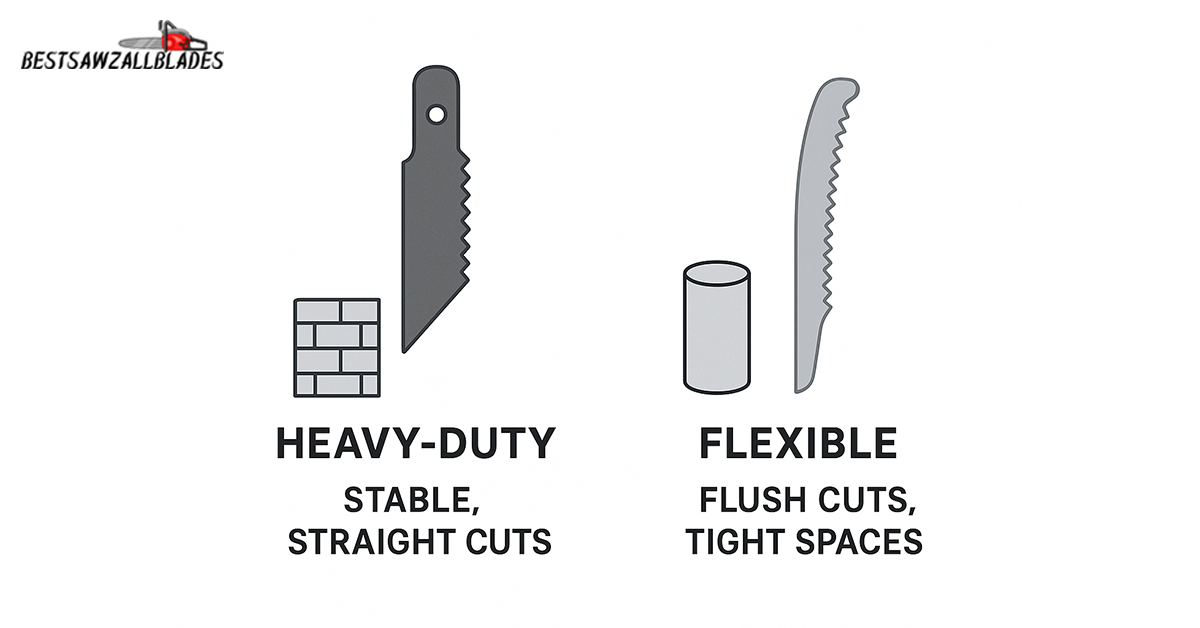

The thickness and width of a blade impact how rigid or flexible it is:

- Thicker blades = more stable and durable. Great for heavy-duty demolition or straight, aggressive cuts.

- Thinner blades = more flexible, ideal for flush cuts or working in tight spaces, though they may wear out faster.

Choosing the right blade thickness and width ensures better control and reduces blade breakage or bending.

How to Choose the Right Sawzall Blade

Picking a Sawzall blade isn’t just about finding one that fits your reciprocating saw; it’s about matching the blade to your material, speed needs, and desired precision. The right choice can make your cuts faster, cleaner, and safer. Here’s how to choose wisely:

- For wood and plastic: Go with a coarse-toothed blade. These offer fast, aggressive cutting, perfect for demolition or quick trim work.

- For metal: Opt for a bi-metal or carbide-tipped blade. They’re built for durability and can slice through nails, pipes, or sheet metal with clean precision.

- For masonry or tile: Use diamond-grit or carbide-coated blades specifically engineered to tackle brick, concrete, ceramic, and other tough materials without wearing out quickly. You might also wonder, Do I need special plaster Sawzall blades? Yes, for plaster, a fine-toothed or carbide-grit blade helps reduce chipping and dust while providing smoother cuts.

For all-purpose jobs: A variable tooth blade is your best bet. Likewise, do Sawzall blades work well on fiberglass? They can, but it’s best to use a fine-toothed carbide blade to prevent fraying and splintering of the fiberglass surface. It’s versatile enough to cut through wood, plastic, and light metals, making it a great option for general home improvement projects.

Choosing the right blade helps you maximize the performance of your Sawzall and ensures smoother, more efficient cutting, no matter the material.

Conclusion

While Sawzall blades aren’t completely universal, they’re designed with enough variety in length, shank type, and material composition to offer excellent flexibility across most reciprocating saw brands. The real secret to success lies in choosing a blade that matches your specific tool compatibility, the material you’re cutting, and the level of performance, whether speed, precision, or durability, you need.

By paying attention to these factors, you’ll get the best results every time, whether you’re tackling a DIY home repair, slicing through metal pipes, or handling a heavy-duty demolition job on a construction site.

And remember: when in doubt, always check your saw’s manual and the blade specs before buying. Ensuring a proper fit can save time, money, and a lot of frustration down the line.

Frequently Asked Questions

Are Sawzall blades universal across all brands?

Are Sawzall blades universal across all brands?

Not completely. Most use a universal shank that fits major brands like Milwaukee, DeWalt, and Bosch, but some older or specialty saws may require brand-specific blades.

How do I know which Sawzall blade is right for my material?

Match the blade to the material:

1.Wood/plastic: Coarse-toothed

2.Metal: Bi-metal or carbide-tipped

3.Masonry: Diamond-grit or carbide-coated

4.Multi-purpose: Variable pitch

What is a universal shank, and why is it important?

A universal shank is a standard blade connector that fits most reciprocating saws, making it easy to use blades across different brands.

Can I use Milwaukee Sawzall blades with other brands?

Yes, Milwaukee Sawzall blades with a universal shank work with most DeWalt, Bosch, Makita, and other popular reciprocating saws.

Do blade length and thickness affect performance?

Definitely. Longer blades are better for deep cuts, while thicker blades offer more rigidity for heavy-duty tasks. Thinner blades are good for precision and tight spaces.

What type of blade should I use for cutting metal pipes or nails?

Use a bi-metal or carbide-tipped blade. These are durable and specifically designed to handle hard metals, nails, and pipes efficiently.

Can one Sawzall blade handle multiple materials?

Some variable pitch blades are designed for general-purpose cutting, but for best results, use material-specific blades to ensure speed, safety, and clean cuts.