A Sawzall, also known as a reciprocating saw, is one of the most versatile power tools in your toolkit. But can it cut through stone and concrete? The short answer is yes, but only if you’re using the right kind of blade. Not every blade is built for this kind of tough job. Using the wrong one can damage both your Sawzall blade and the saw itself. This is why using the right blade is efficient and time-saving; it lets you cut faster, with less effort, and avoids unnecessary wear on your tool.

While carborundum discs have traditionally been used to cut steel-reinforced concrete, most pros now prefer diamond-coated Sawzall blades. They’re not only more affordable than ever, but they also offer impressive durability and cutting efficiency.

Want to know which blades truly work? Discover the best Sawzall blades for cutting concrete and stone, and learn expert tips for using them effectively without damaging your tool or material.

Saw Blades for Cutting Concrete and Stone

Sawzall blades come in many shapes and materials, but they’re not all interchangeable. While some people ask if Sawzall blades are universal or interchangeable, the truth is that masonry-rated blades are designed for a very different purpose than wood or metal blades.”

Sawzall blades are incredibly popular for cutting materials such as metal, wood, and plastic; however, when it comes to concrete and stone, the requirements become a bit more specific. You can’t just use any standard blade. To tackle these tougher materials, you’ll need specialized reciprocating saw blades designed for heavy-duty cutting.

Look for diamond-grit or carbide-tipped Sawzall blades. These are built to handle the hardness and abrasiveness of concrete and masonry without wearing down too quickly or damaging your tool. The right blade makes all the difference when cutting through concrete blocks, stone pavers, or even reinforced concrete.

When choosing a blade, also check its TPI (teeth per inch) rating. What does TPI mean on a Sawzall blade, and why does it matter? Higher TPI means smoother, slower cuts, while lower TPI is better for faster, rougher cuts in tough materials like masonry.”

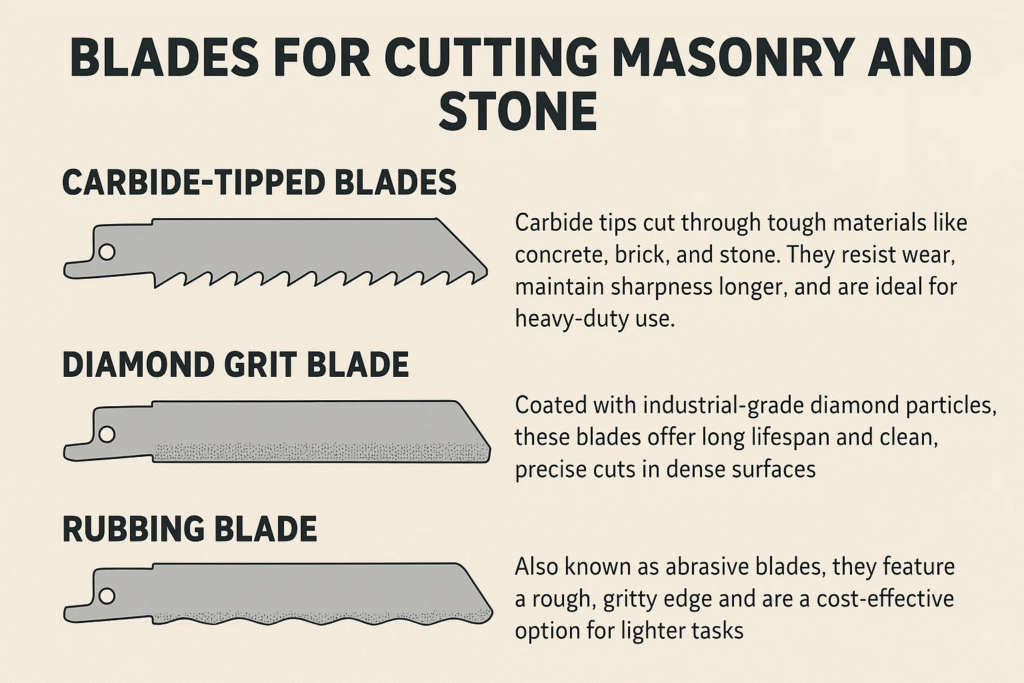

Blades with a Carbide Tip

- Carbide-tipped blades are a game-changer when it comes to cutting tough materials. Their tips are made from tungsten carbide, one of the hardest and most durable materials available, perfect for powering through concrete, brick, and stone with ease.

- Unlike standard steel blades, Sawzall blades with carbide tips are built to last. They resist wear, maintain their sharpness longer, and won’t break down quickly even during heavy-duty cutting. If you’re tackling masonry or stonework, these are the blades you can count on for clean, efficient cuts.

Diamond Grit Blade

- Diamond grit blades are another top-tier option when it comes to cutting through stone, brick, and concrete. These blades are coated with industrial-grade diamond particles, allowing them to slice through the toughest materials with minimal effort.

- What makes a diamond Sawzall blade stand out is its long lifespan and ability to deliver clean, precise cuts, even in dense surfaces like cement or masonry blocks. If you want smooth results without wearing down your blade quickly, a diamond-coated blade is the perfect tool for the job.

Blades for Rubbing

- Rubbing blades, also known as abrasive blades, are designed with a rough, gritty edge made from hard materials that can grind through stone, concrete, and brickwork with ease.

- Although they don’t last as long as diamond-coated or carbide-tipped Sawzall blades, they’re still a smart, cost-effective option for small masonry jobs or occasional use. If you’re on a budget and need to handle lighter tasks, an abrasive blade can be a solid choice.

Can You Use a Standard Sawzall Blade?

Not really, standard Sawzall blades are typically designed for cutting wood or metal, not heavy-duty materials like concrete or stone. As explained in our other guide, Can Sawzall Blades Cut Concrete and Stone?, the answer is yes, but only with the right blade.

If you attempt to cut hard materials using a regular reciprocating saw blade, you’ll quickly dull the edge, get poor results, and even risk damaging your saw. Many beginners wonder why Sawzall blades break and how to prevent it. In most cases, it’s due to using the wrong blade type, applying too much pressure, or overheating during the cut.” For cutting masonry, brick, or concrete, always use specialized carbide-tipped or diamond-grit blades that are built for the job.

How to Cut Concrete and Stone with a Sawzall

Choose the Right Blade:

The first step is selecting a blade that’s built for the job. For cutting through concrete, brick, or stone, go with a carbide-tipped or diamond grit Sawzall blade. Always check the label to ensure it’s rated for masonry cutting.

Secure the Material:

Make sure your concrete or stone surface is stable and properly supported. Cutting loose or unstable material can be dangerous and lead to inaccurate cuts or tool damage.

Go Slow and Steady:

Start with light pressure and let the reciprocating saw blade do the work. Gradually increase pressure as the blade bites in. A slow, steady approach helps you make clean, precise cuts without burning out the blade or motor.

Keep the Blade Cool:

Cutting hard materials generates a lot of heat. To avoid overheating, pause periodically to let the blade cool or lightly spray water during the cut. This not only extends blade life but also improves performance when working with stone and concrete.

Conclusion

Yes, a Sawzall can cut through concrete and stone, but only if you’re using the right blade for the job. Depending on the material, carbide-tipped, diamond grit, or abrasive blades are all solid choices for powering through tough surfaces without damaging your tool.

To get the best results, always make sure the material is properly secured, use a slow and steady cutting motion, and give your blade time to cool down. This will not only give you a cleaner cut but also extend the life of both your blade and saw.

In the world of power tools, a reciprocating saw (Sawzall) is a must-have. With the right setup, it’s incredibly versatile and capable of cutting through a variety of tough building materials, including stone, brick, and concrete.

Frequently Asked Questions

What is a Sawzall?

A Sawzall, also known as a reciprocating saw, is a powerful handheld tool designed to cut through a wide variety of materials. It uses a back-and-forth (reciprocating) motion to make fast, aggressive cuts, making it a favorite for demolition, remodeling, and tough jobs.

Can a Sawzall blade cut through concrete and stone?

Yes, but only with the right type of blade. To handle the toughness of concrete and stone, you’ll need Sawzall blades made with tungsten carbide or coated in diamond grit, which are engineered to cut through abrasive, dense materials.

What type of blade should I use for cutting concrete or stone?

The best options are diamond-grit Sawzall blades or carbide-tipped blades specifically labeled for use on masonry, stone, or concrete. These blades are tough enough to handle the density and abrasiveness of these materials without quickly wearing out.

Can standard Sawzall blades cut through concrete and stone?

No, standard reciprocating saw blades made for wood or metal aren’t strong enough for concrete or stone. Using one can lead to dull blades, poor cuts, or even tool damage. Always use specialty blades built for masonry work.

How thick of concrete or stone can a Sawzall cut?

That depends on the power of your Sawzall and the type of blade you’re using. With a diamond blade, you can typically cut up to 1–2 inches deep. For thicker slabs or stone, you may need a more heavy-duty tool like a concrete saw or cut-off saw for better performance.