When you’re shopping for the best Sawzall blade, you’ll often come across the term “TPI”, which stands for Teeth Per Inch. This simple yet crucial spec tells you how many teeth are packed into each inch of the blade. But why does it matter? Because TPI plays a big role in how your blade cuts, from the speed and smoothness of the cut to its efficiency on different materials like wood, metal, or plastic.

Understanding TPI is key to picking the right reciprocating saw blade for your job. Whether you’re after fast, rough cuts or clean, precise finishes, knowing the right TPI can make all the difference. In this guide, we’ll break down what TPI means and how it helps you choose the best Sawzall blades for every type of project.

What Is TPI on a Sawzall Blade?

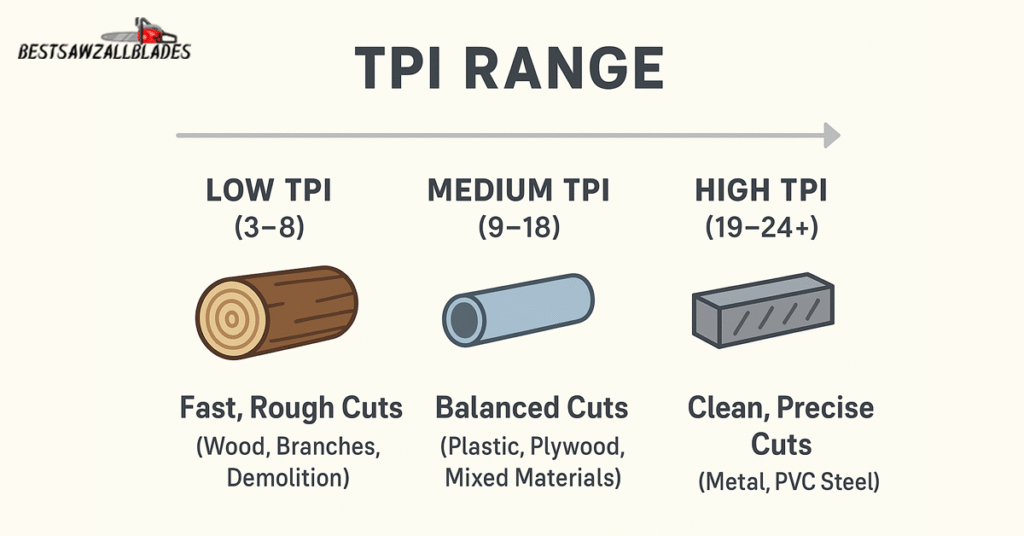

TPI, or Teeth Per Inch, is a key spec to understand when choosing a Sawzall blade (also known as a reciprocating saw blade). It tells you how many teeth are packed into a one-inch stretch of the blade. This number affects how fast, aggressive, or smooth your cuts will be. Generally, the lower the TPI, the faster but rougher the cut; the higher the TPI, the smoother and cleaner the result.

- Low TPI (3–8): Ideal for fast, aggressive cuts in soft materials like wood and tree branches. These blades rip through material quickly but leave a rough finish.

- Medium TPI (9–18): Great for plastic, plywood, and non-ferrous metals. Offers a balance between cutting speed and smoothness, perfect for general-purpose use.

- High TPI (19–24+): Best for cutting hard materials like steel, iron, or stainless steel. Also works well for making fine, clean cuts in wood and laminate.

Whether you’re demolishing a wall, trimming pipes, or working with sheet metal, picking the right Sawzall blade TPI will help you get the job done more efficiently and cleanly.

Why Does TPI Matter on a Sawzall Blade?

When it comes to Sawzall blades, TPI (Teeth Per Inch) plays a crucial role in determining how the blade performs across different materials. It directly affects key cutting factors like speed, smoothness, material compatibility, and even the lifespan of the blade.

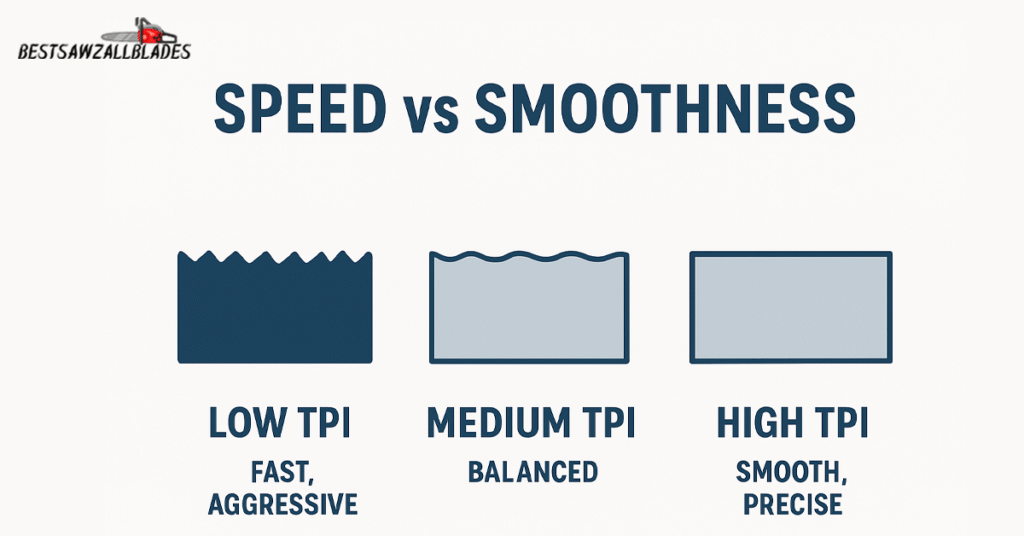

Cutting Speed

- Low TPI (3–8) blades have larger, widely spaced teeth that remove more material per stroke, perfect for fast, aggressive cuts in softwood, drywall, or tree limbs.

- High TPI (19–24) blades cut slower but with greater precision, making them ideal for hard plastics, thin metals, and other materials where accuracy matters.

Cut Quality

- Lower TPI blades produce rough, jagged cuts, great for demolition or rough carpentry, but can splinter delicate materials.

- Higher TPI blades offer smooth, clean cuts in harder materials like steel, aluminum, or PVC, with less need for sanding or cleanup afterward.

Material Compatibility

- Low TPI = best for wood, plastic, and soft materials.

- Medium TPI (9–18) = versatile for wood, PVC, and non-ferrous metals.

- High TPI = tailored for metal cutting, hard plastics, and even stainless steel with precision.

Blade Life & Durability

Sawzall blades often break when used on the wrong material, bent at awkward angles, or overheated from friction. To prevent breakage, match the blade TPI to the material, avoid forcing the saw, and use lubricants on metal cuts when needed. Investing in bi-metal or carbide blades can also dramatically reduce breakage. Using the wrong TPI blade for a job can quickly wear it out or damage your saw.

- A low TPI blade on metal will dull fast and overheat.

- A high TPI blade on softwood can clog, overwork your saw, and reduce efficiency.

Choosing the right Sawzall blade TPI not only boosts performance but also ensures a longer-lasting tool and cleaner cuts.

In short, TPI matters because it helps you cut faster, cleaner, and smarter, saving you time, effort, and replacement costs.“This is why using the right blade is efficient and time-saving. Not only does it cut faster and cleaner, but it also prevents overheating, clogging, or premature dulling.”

How to Choose the Right TPI for Your Project

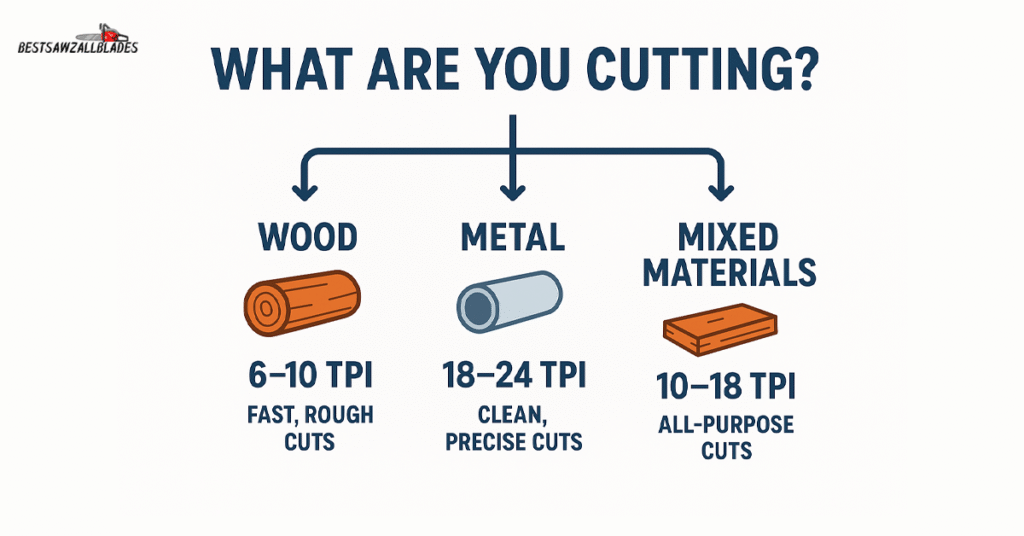

Selecting the right TPI (Teeth Per Inch) for your Sawzall blade depends on two main factors: what you’re cutting and how clean or fast you need the cut to be. Here’s a quick guide to help you match the TPI to your task:

Cutting Wood

Go with a low TPI blade (6–10 TPI). These blades have larger teeth that make quick, rough cuts, perfect for demolition work, framing, pruning, or any job where speed is more important than precision.

Cutting Metal

Choose a high TPI blade (18–24+ TPI). These finer-toothed blades cut smoothly through hard metals like steel, copper, aluminum, and iron with minimal sparks, vibration, or edge damage, ideal for plumbing or sheet metal work.

Cutting Mixed Materials

For situations like cutting wood with nails, or pipes embedded in walls, a medium TPI blade (10–18 TPI) is your best bet. It provides balanced performance, capable of handling both soft wood and non-ferrous metals efficiently. Many people ask if Sawzall blades are universal or interchangeable, and the answer is yes. Most reciprocating saws accept standard blade shanks, so you can swap blades between brands, as long as you choose the right TPI and material type.”

For Precision & Fine Cuts

If your project requires clean, sharp, and controlled cuts, especially in thin materials or finish work, go with a high TPI blade (20+ TPI). These blades reduce splintering and leave a smooth, professional finish with minimal cleanup.

By matching the right Sawzall blade TPI to your project, you ensure better results, longer blade life, and less strain on your saw.

Conclusion

The TPI (Teeth Per Inch) of a Sawzall blade plays a vital role in determining how fast, smooth, and efficient your cuts will be. For quick, aggressive cuts in soft materials like wood or drywall, a low TPI blade is your go-to choice. When working with harder materials such as metal, steel, or PVC, a high TPI blade ensures cleaner, more precise results.

Choosing the right TPI for your specific cutting task improves not only the cut quality but also extends the life of your blade and reduces wear on your saw. Whether you’re tackling demolition, remodeling, plumbing, or fine finish work, the correct TPI makes your job faster, cleaner, and much more effective. Always match your blade to the material and the cut you need, for the best Sawzall performance, it’s all in the teeth.

Frequently Asked Questions

What TPI is best for cutting wood?

For fast, rough cuts in wood, a Sawzall blade with 6 to 10 TPI is ideal. These low TPI blades have larger teeth that quickly tear through softwood, plywood, and even tree branches, making them perfect for demolition or framing tasks.

What TPI should I use for cutting metal?

When cutting metal like steel, copper, or aluminum, opt for a blade with 18–24+ TPI. These high TPI blades offer precision and smoother edges, reducing the chance of burrs or damage to the material.

Can a single blade handle different materials?

Yes, there are multi-purpose Sawzall blades with a medium TPI (10–14) that can cut through both wood and soft metals. While they’re convenient for mixed-material jobs, specialty blades matched to each material will always deliver better performance and cleaner cuts.

Why does a high TPI blade cut slower?

Blades with higher TPI have smaller, closely spaced teeth, which means they remove less material with each stroke. This increases friction and slows down the cut, but in return, you get greater accuracy and a cleaner finish.

Does TPI affect blade life?

Absolutely. High TPI blades often last longer for detailed or precision work since each tooth handles less stress. However, using the correct TPI for your material is key; otherwise, you risk dulling or damaging the blade prematurely.